Work instructions are a key tool for stable, safe, and efficient processes in everyday operations. They translate overarching processes and procedural instructions into concrete, executable steps, thereby creating clarity for employees directly at their workplace. Well-structured and practically developed work instructions reduce errors, ensure quality, accelerate training time, and at the same time enable continuous improvement through standardized, traceable work.

1. Align With the Hierarchy

Work instructions should always reference the relevant procedure (SOP) and process. This traceability ensures that every task is performed in support of higher-level business objectives and consistent ways of working.

2. Develop at the Workstation, With End Users

Observe the process in action: Draft instructions where the work actually happens, collaborating with the people who perform the task. This ensures instructions are relevant, feasible, and clear for real-world conditions.

3. Use a Standardized, Clear Structure

An effective work instruction typically includes:

Title and Objective: Clearly state the task and expected outcome.

Scope and Applicability: Specify who will use it and when.

Tools and Materials: List everything required.

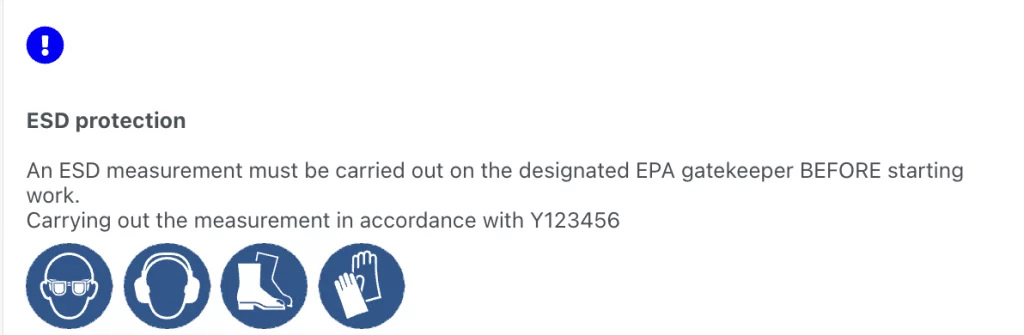

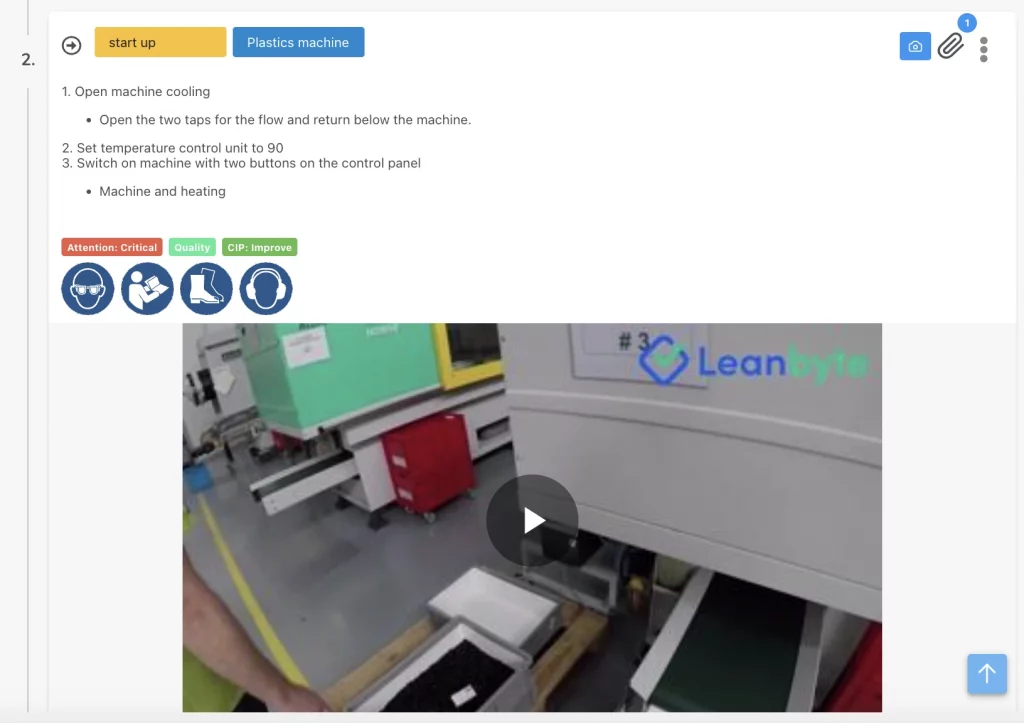

Safety and Precautions: Highlight hazards, PPE, and key safety steps.

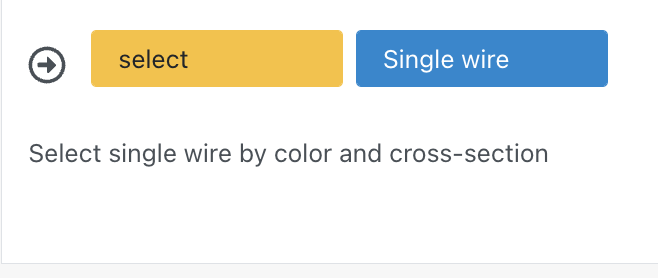

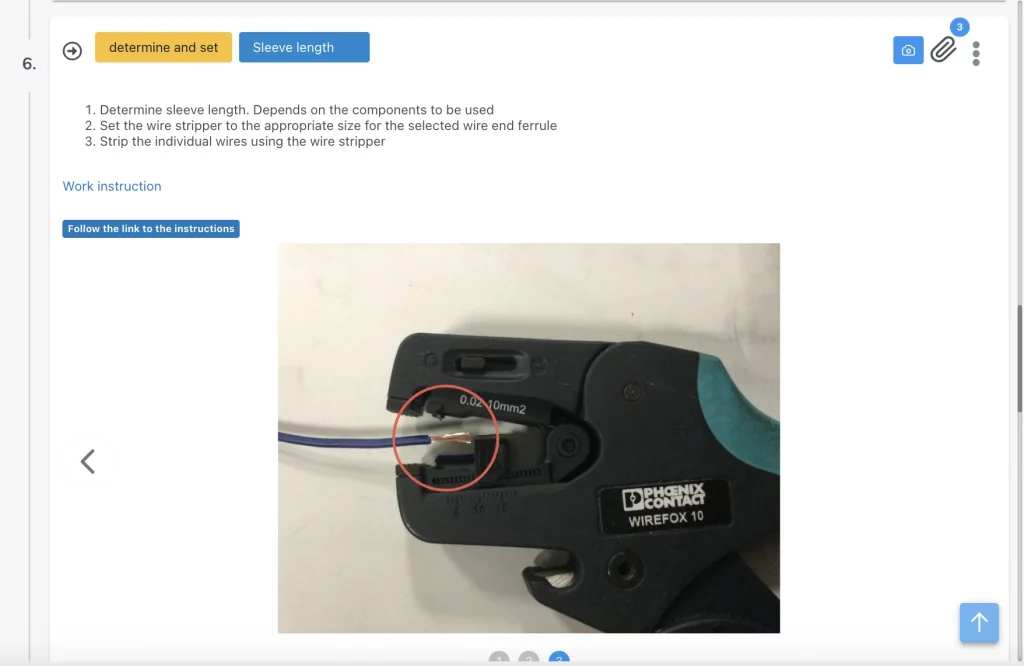

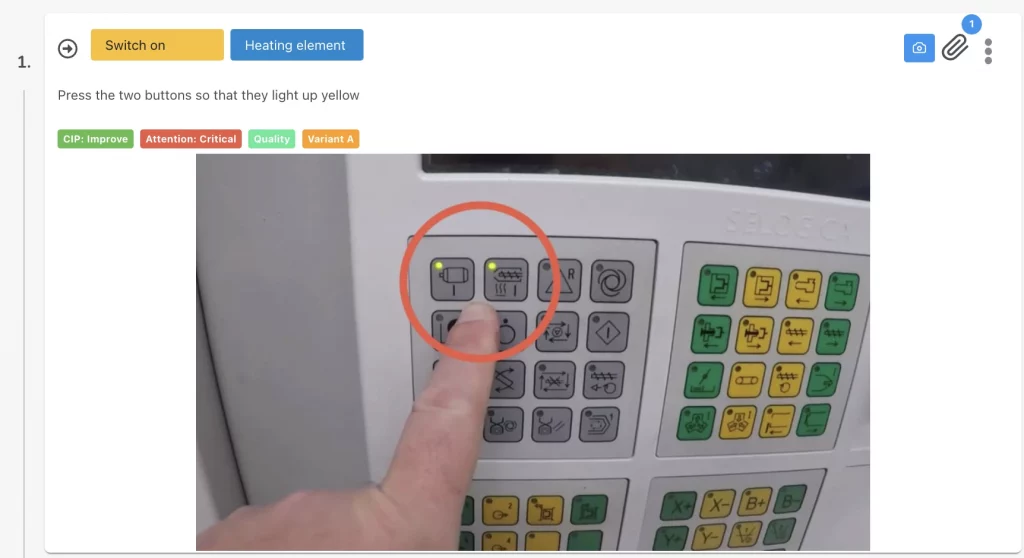

Step-by-Step Guidance: Present each step as a simple, actionable instruction, in the exact sequence needed. Use numbered or bulleted lists and avoid long paragraphs.

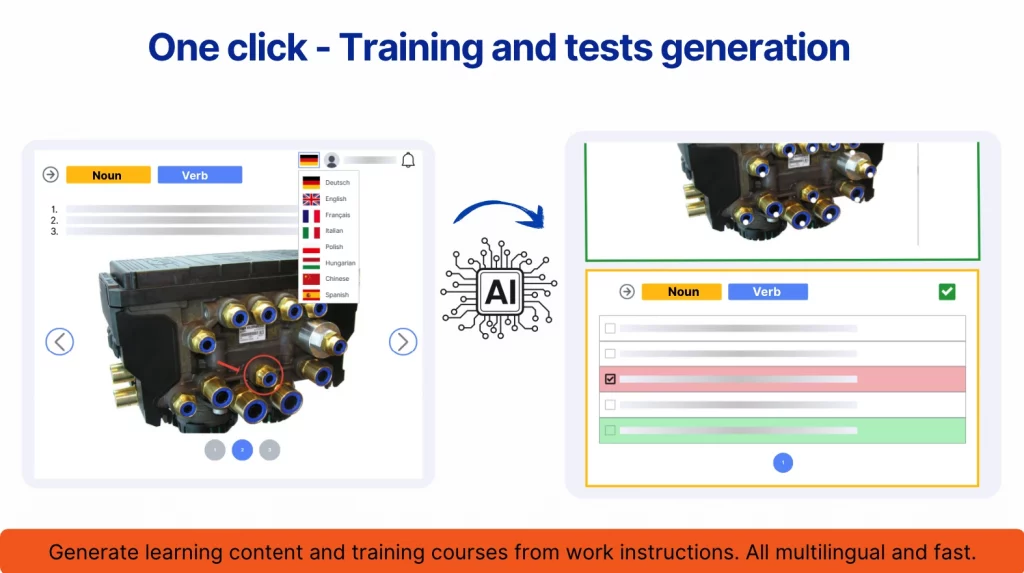

- Visual Aids: Integrate annotated photos, diagrams, or videos to clarify complex steps.

Key Points and Reasons: Explain the ‘why’ behind crucial steps, especially those tied to quality or safety.

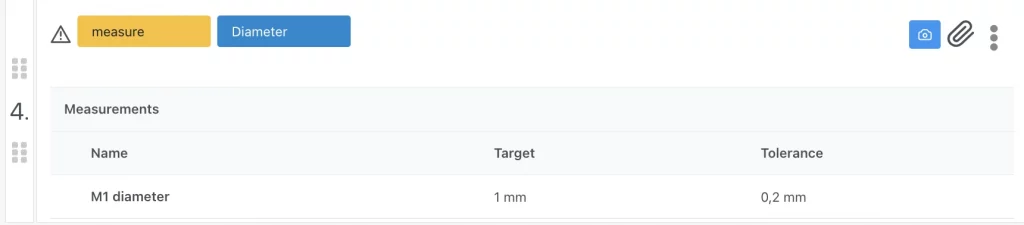

Quality Control Checks: Detail inspections, measurements, or standards to be met as the task is performed.

Troubleshooting and FAQs: Include guidance for common errors or exceptions.

4. Use Simple, Action-Oriented Language

Keep instructions concise and use active verbs (e.g., “Press – green button,” not “The button should be pressed”). Avoid ambiguity, technical jargon, or overloaded steps

5. Make Instructions Accessible and Visual

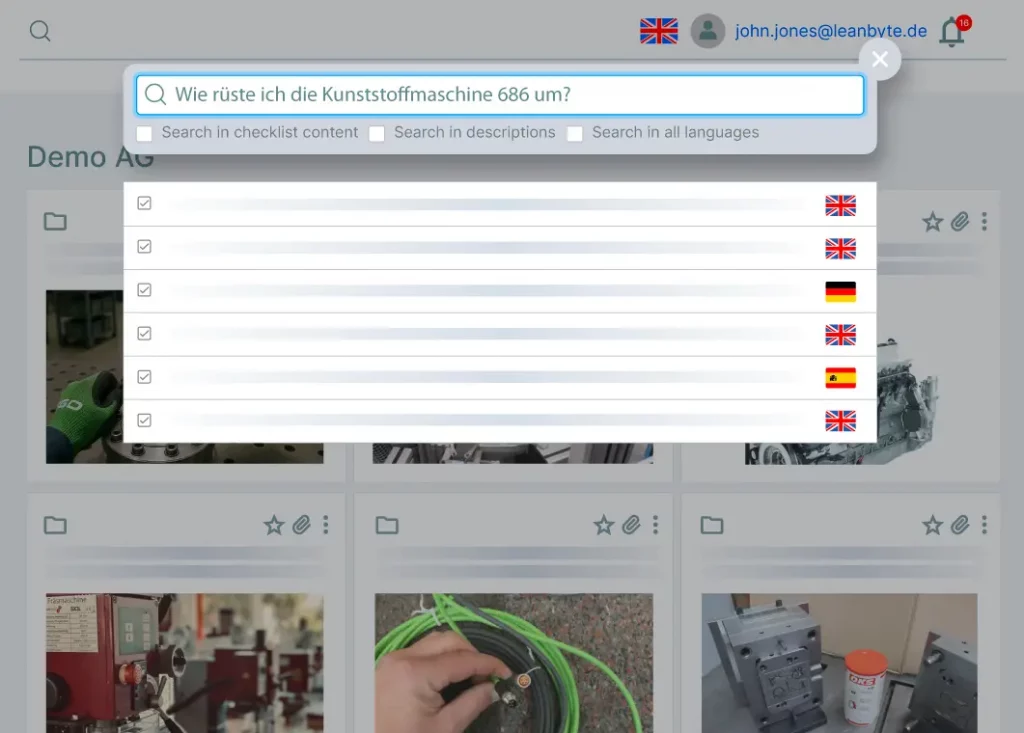

Ensure instructions are easy to find at the point of use—digitally or physically.

Prioritize visual clarity with well-labeled diagrams, before/after photos, and clear step demarcation

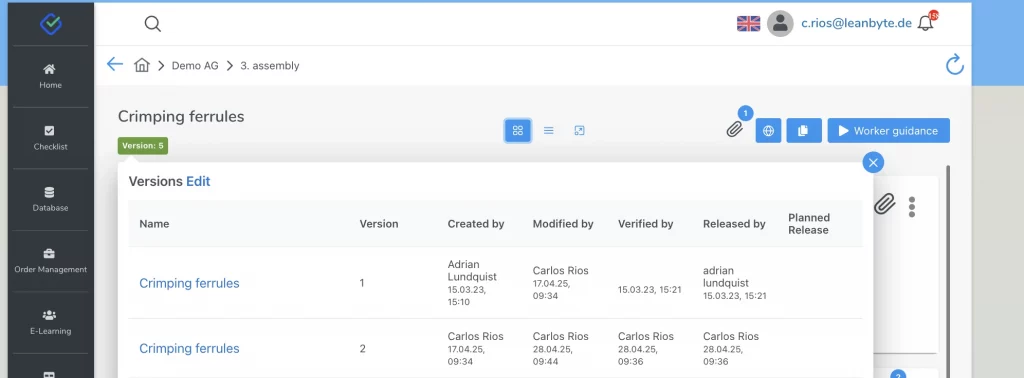

6. Foster Feedback and Continuous Improvement

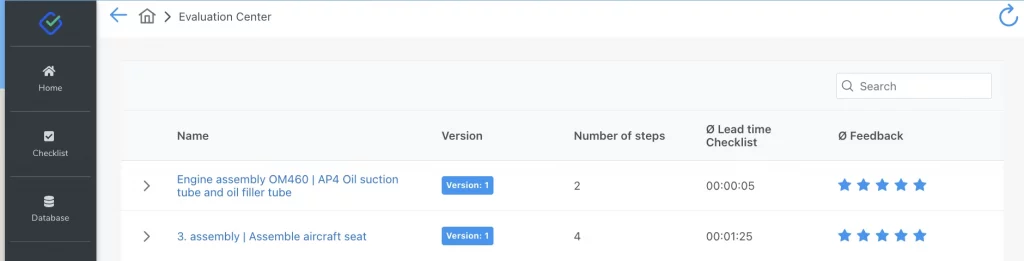

Involve operators regularly in reviewing, testing, and refining instructions.

Update instructions frequently—especially after process changes, problems, or improvement projects. Work instructions are ‘living documents’.

7. Ensure Training and Compliance

Integrate work instructions into training programs for new and existing staff.

Periodically audit usage and adherence to ensure instructions are effective and followed in daily operations.

Template Example

Section | Description |

|---|---|

Title | “Changing Filter on Machine X” |

Objective | Ensure correct, safe, and timely replacement of filter |

Scope | Applies to all operators on shift A & B for weekly maintenance |

Tools/Materials | Filter Type Z, 10mm wrench, Gloves |

Safety Precautions | Turn off power, Lockout/Tagout (LOTO), wear gloves |

Step-by-Step Tasks | 1. Power off machine 2. Remove panel 3. Unscrew old filter 4. Fit new filter |

Visual Aids | Annotated photo showing filter location |

QC Checks | Confirm pressure reading in green range before restarting machine |

Troubleshooting | If unable to remove old filter, contact supervisor |

Summary Table: Work Instruction Creation Guidelines

Principle | Action |

|---|---|

Context Alignment | Connect to procedure/process; reference purpose/scope |

User Involvement | Co-create at workstation with operators |

Structured Detailing | Title, scope, tools, safety, sequenced steps, visuals, QC checks |

Clarity and Simplicity | Use action verbs, clear language, one action per step |

Accessibility | Provide at point of use, visual layout, easy updates |

Continuous Improvement | Gather feedback, update regularly, integrate lessons learned |

Compliance & Training | Use in onboarding, audit for adherence, update after process change |

Fazit

In conclusion, normal work instructions should be created as actionable, highly detailed guides for frontline staff, strictly adhering to the structure and context set by higher-level procedures and processes. Their creation must be collaborative, visual, and iterative, enabling both operational consistency and continual improvement.