AI-powered standardization, qualification, and quality assurance.

- Faster onboarding

- React flexibly to changes

- Ensure global quality standards

Trusted by top production and operational excellence teams

Manufacturing Qualification System - MQS

Worker Assistance

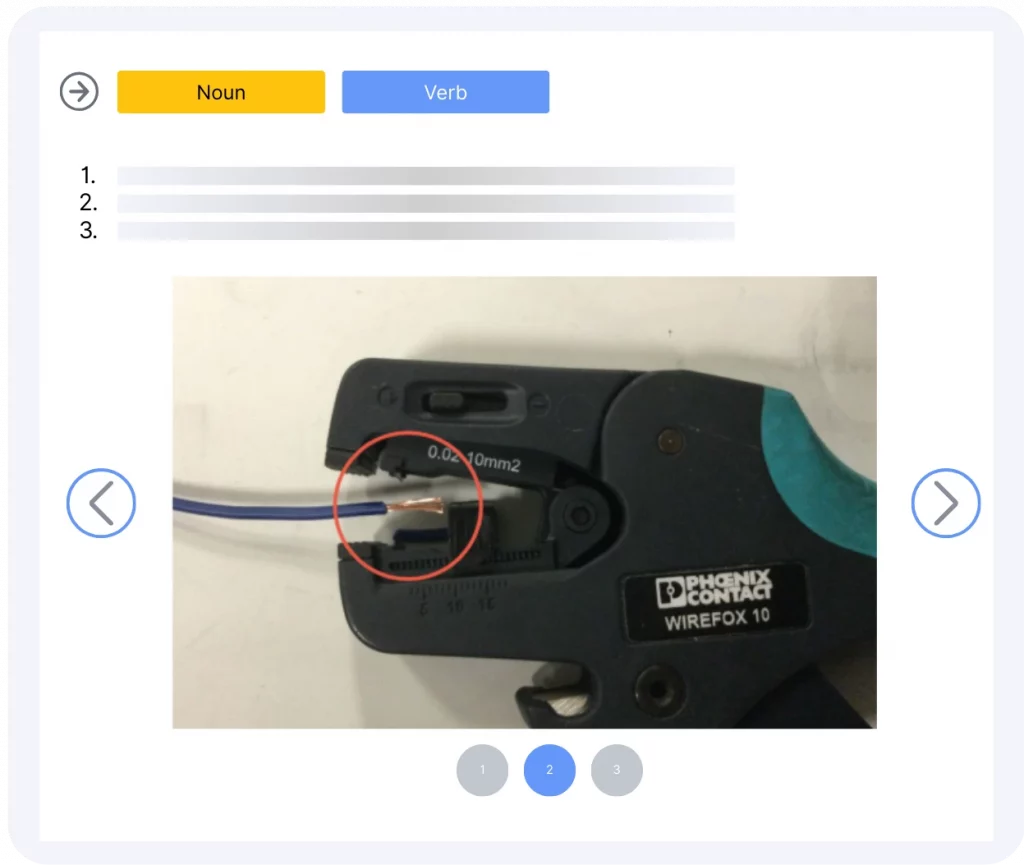

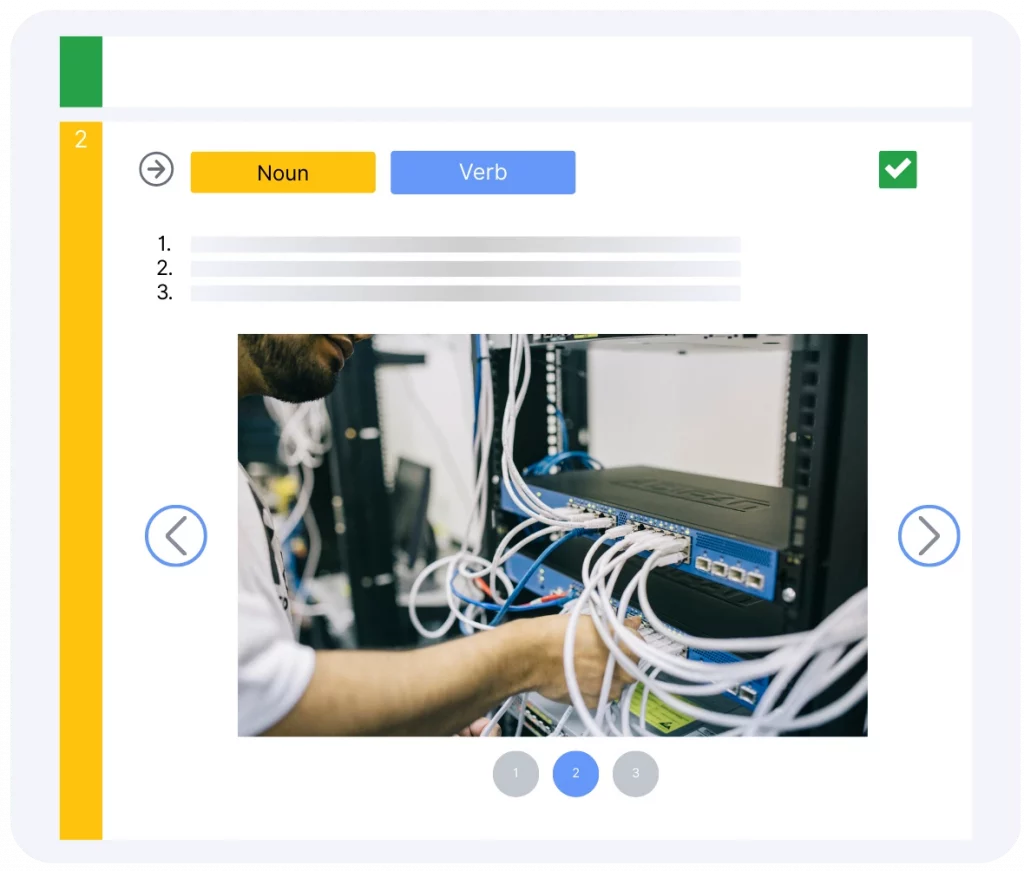

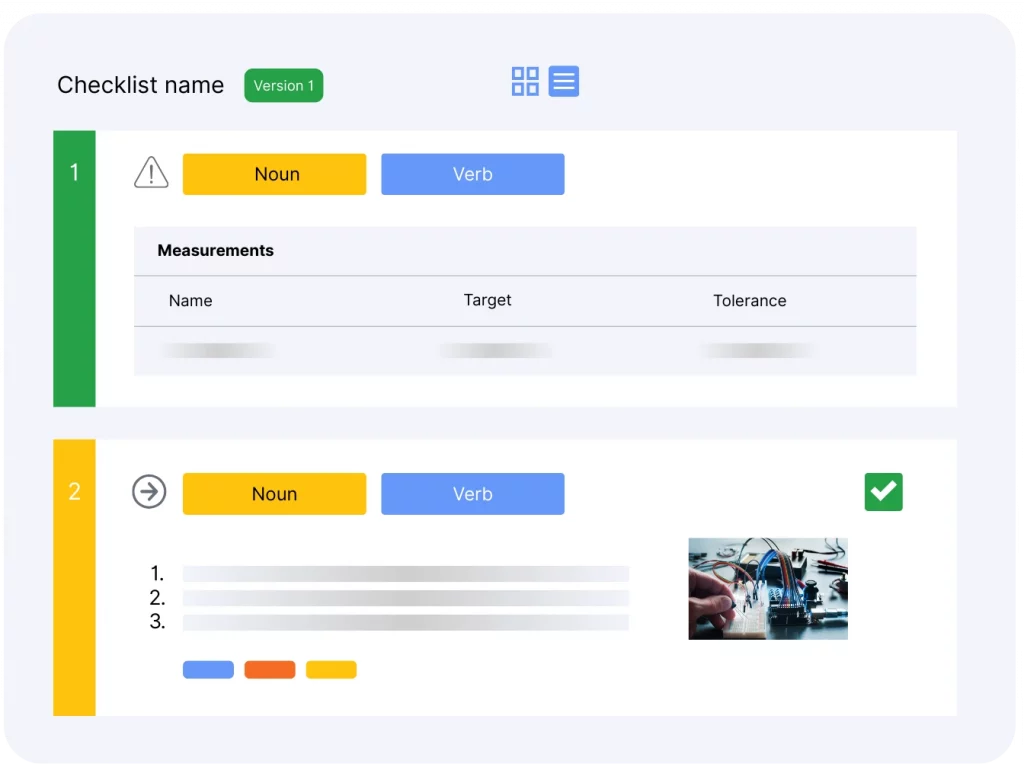

Guide workers step by step with multilingual standardized work instructions and checklists to ensure process compliance whenever they need.

Manage your ERP work orders efficiently and track their progress in real time.

Skills Management and Training

Deliver training and track compliance with an automatically updated skills matrix for real-time workforce insights.

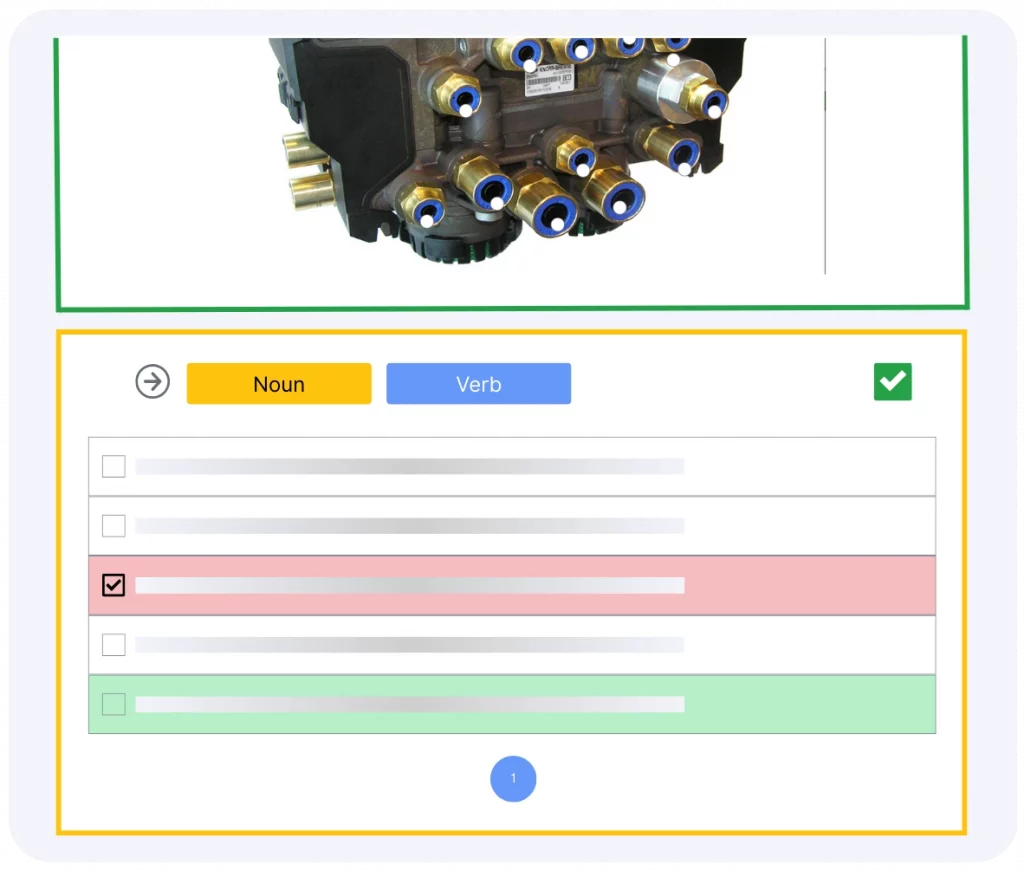

Validate knowledge retention with multimedia content, visual assessments and simulations and analyze test results to optimize training materials.

Digital Work Instructions

Capture expert knowledge easily and securely, with enterprise-grade protection.

Ensure consistency by standardizing and documenting processes.

Enable seamless multilingual communication and knowledge sharing across your global workforce with flexible, intelligent translation tools.

Data Analysis and Optimization

Analyze data across processes, checklists, training, and e-learning modules to drive insights and improvements.

Enable real-time analysis of work orders to enhance decision-making and planning.

E-Learning

Guidance

Analysis

Manufacturing Qualification System - MQS

E-Learning

Guidance

Analysis

Digital Work Instructions

Capture expert knowledge easily and securely, with enterprise-grade protection.

Ensure consistency by standardizing and documenting processes.

Enable seamless multilingual communication and knowledge sharing across your global workforce with flexible, intelligent translation tools.

Skills Management and Training

Deliver training and track compliance with an automatically updated skills matrix for real-time workforce insights.

Validate knowledge retention with multimedia content, visual assessments and simulations and analyze test results to optimize training materials.

Worker Assistance

Guide workers step by step with multilingual standardized work instructions and checklists to ensure process compliance whenever they need.

Manage your ERP work orders efficiently and track their progress in real time.

Data Analysis and Optimization

Analyze data across processes, checklists, training, and e-learning modules to drive insights and improvements.

Enable real-time analysis of work orders to enhance decision-making and planning.

Save time and money with us

Faster onboarding

Lower error rate

More productivity

What production market leaders say about Leanbyte

Leanbyte is the result of years of experience. What started at Daimler Truck, we’ve taken to a whole new level – a solution that truly works in practice and delivers measurable value.

Prof. Dr. Volker Engert

Co-Founder & Head of Operations, Knowledge Management Expert with 30 Years at Daimler Trucks

Leanbyte enables us to document production knowledge uniformly across all locations. This makes the transfer of knowledge simple and practical, which also significantly shortens the onboarding of shopfloor workers.

Jens Jäger

Operational Excellence at Chiron Group

Quickly and easily, we digitally documented all work instructions, checklists, qualification materials, and training sessions. It is easy to use, and changes are implemented quickly.

Philipp Rühlemann

Operations Manager LC Rotenburg

Leanbyte brings together what is often treated separately in many companies: clear process documentation, continuous improvement, inspiration for new ideas, workforce qualification, process knowledge, and worker guidance. What impressed me most was the rapid rollout — not a months-long project, but a lean start with immediate, tangible value. The platform makes experiential knowledge accessible and transferable — essential for real, lasting improvement. Moreover, Leanbyte enables a deeper and more forward-looking approach to process improvement than traditional methods allow.

Hermann Doppler

Board Member, Vice President, Peter Drucker Society Mannheim e.V.

Digitalization is no longer a question of if, but rather how. By providing a comprehensive qualification management system on a single platform, Leanbyte gives companies a significant advantage – saving time, reducing coordination efforts, and delivering real efficiency gains for operational teams.

Andreas Klein

Professor of Controlling and Entrepreneurship at SRH University Heidelberg

Frequently asked

questions FAQ

1 What is MQS?

MQS stands for Multilingual Qualification System. It is an AI-powered platform designed to streamline process standardization, employee qualification, and continuous improvement in production environments.

By combining worker guidance, digital work instructions, and multilingual training, MQS helps manufacturers build a skilled workforce, ensure consistent processes, and adapt quickly to changing requirements. This enables companies to increase efficiency, maintain high quality standards, and strengthen their competitiveness across global operations.

2What is the difference between MES, LMS, and MQS?

MES (Manufacturing Execution System), LMS (Learning Management System), and MQS (Multilingual Qualification System) each address different operational needs:

- MES focuses on monitoring and managing production processes in real-time.

- LMS provides structured training content and tracks learning progress.

- MQS, developed by Leanbyte, combines multilingual worker guidance, digital work instructions, and qualification management into one seamless solution—specifically designed to enhance flexibility and efficiency on the shop floor.

3Who is Leanbyte for?

Leanbyte is built for manufacturers and industrial companies aiming to digitize and optimize shop floor operations. Our solutions are designed for production managers, team leads, and operational excellence professionals who want to increase productivity, reduce waste, and ensure quality—while empowering employees through clear guidance and qualification tools.

4How does Leanbyte support lean methodologies?

Leanbyte is rooted in lean principles. Our platform eliminates non-value-adding processes by enabling standardization, real-time transparency, and continuous improvement. Features like digital work instructions, qualification tracking, and visual worker guidance help reduce errors, shorten learning curves, and drive operational efficiency.

5Can I customize Leanbyte for my team's workflow?

Yes. Leanbyte is designed to adapt to your specific processes. Whether it’s defining custom qualification paths, adapting work instructions, or tailoring roles and access rights, our system provides the flexibility you need to align with your unique operational requirements.

6Does Leanbyte support integrations with other tools?

Yes, integrations are possible based on your needs. Leanbyte provides API access and offers the possibility to connect with a wide range of enterprise systems—such as ERP, MES, HR platforms, and document management tools. Our team works closely with you to implement the integrations that support your workflows and ensure efficient data flow.

7How does Leanbyte ensure the safety of our cloud data?

Leanbyte provides a secure and reliable platform built on Microsoft Azure Active Directory. We support two-factor authentication, granular user access management, and host all data in GDPR-compliant, ISO 27001-certified data centers located in the EU. This ensures that your data is protected according to the highest industry standards.

8 Is Leanbyte cloud-based or on-premise?

Leanbyte offers both cloud-based and on-premise deployment options. This flexibility allows organizations to choose the setup that best fits their IT infrastructure, compliance requirements, and operational needs. Whether you prefer the scalability and convenience of the cloud or the control of an on-premise solution, Leanbyte adapts to your environment.

9 Does each employee need to have their own device to use Leanbyte?

Not necessarily. Leanbyte is designed to be flexible in various production environments. Shared devices like tablets or terminals can be used at workstations, allowing multiple users to log in securely and access their personalized instructions or training modules as needed.

Get in touch

Drop us a line for a fast response.